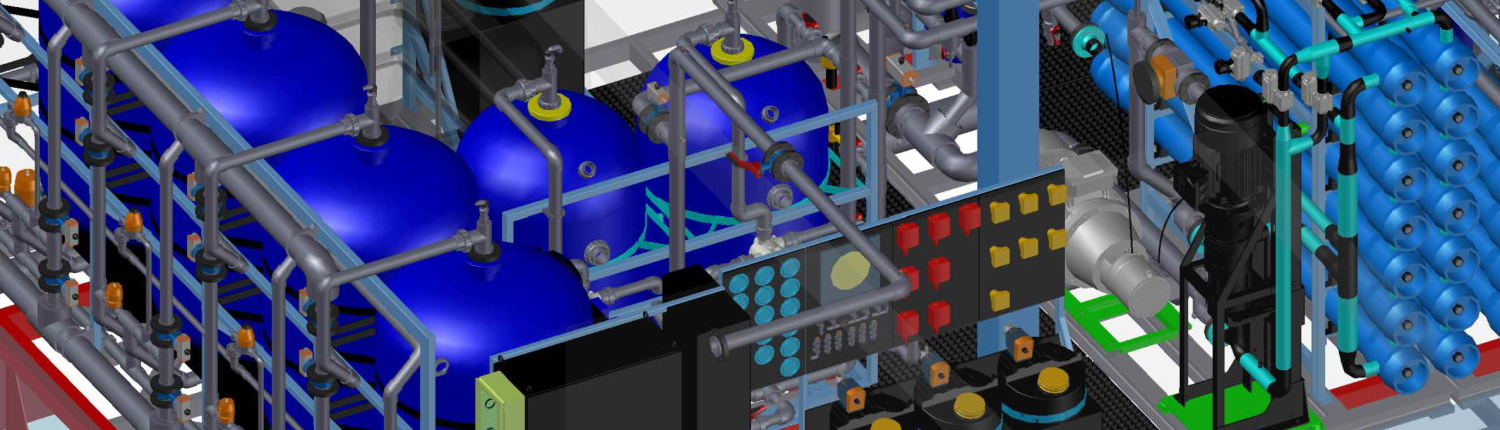

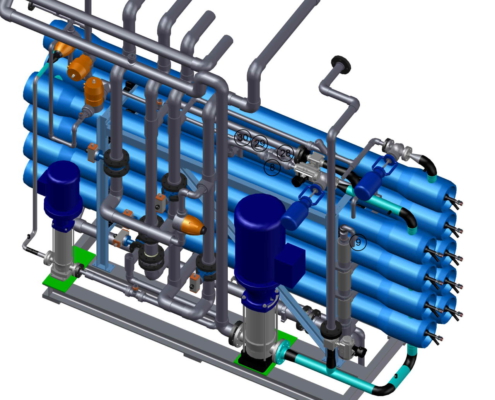

Reverse Osmosis (RO)

The most commonly used process for seawater desalination is reverse osmosis. The seawater is desalinated under high pressure via a reverse osmosis membrane. The product water is salt-free water of drinking water quality. The reverse osmosis plant is preceded by a filtration plant to filter solids from the seawater. The filtration plant is backwashed fully automatically during ongoing reverse osmosis operation without stopping drinking water production. Common reverse osmosis plants produce water volumes between 20 and 2000 tons per day. The plant technology can be adapted to individual needs, available space and required water volumes. The regularly required chemical maintenance cleaning of the reverse osmosis membranes runs fully automatically. The cleaning tank required for this is included in the scope of supply of the plant.

In a second reverse osmosis stage, a partial stream can very easily be treated in parallel up to “Technical Water Quality”. This second stage can be switched on or off permanently in parallel with the operation, as required.

The plant technology is fully automated and can be operated via simple push buttons. The operating data of the plant technology are displayed in a touch panel. Operating parameters can also be adjusted there.

Benefits

- Long life membrane system

- High energy efficiency

- Lowest consumption of consumables

- High quality materials

- Best available maintenance concept

- State of the Art Engineering and design

- Capacity as demanded from 20-1500 t/d

- Up to three passes to achieve quality as needed

- Temperature from 5-35°C

- Fully automated systems

- Comfortable Visualization